Wie der 3D-Druck in der Automobilindustrie genutzt wird.

Eine besondere Entwicklung in der Automobilindustrie ist in der letzter Zeit der 3D-Druck. Wenn Sie ernsthaft glauben, dass die Automobilindustrie hinsichtlich dieser Entwicklung im Rückstand ist, sollten Sie sich diesen Artikel genau durchlesen. Autohersteller verstehen die Vorteile dieser Technologie zu nutzen und sind sogar führend in der Anwendung.

Wenn sich die aktuellen Trends fortsetzen, wird der 3D-Druck in der Automobilindustrie dank seines bisherigen Nutzens und zukünftiger Innovationen, die die Technologie verwendet, weiterhin noch mehr an Bedeutung gewinnen.

Ford.

Ob Sie es glauben oder nicht, Ford verwendet seit den 1980er Jahren den 3D-Druck. Somit kann das Unternehmen als Early Adopter bezeichnet werden, denn zu jener Zeit hatten die Menschen keine Ahnung, dass es so etwas gibt. Im Jahr 2017 produzierte Ford insgesamt ca. 500.000 Fahrzeugteile, die mit einem 3D-Drucker hergestellt wurden.

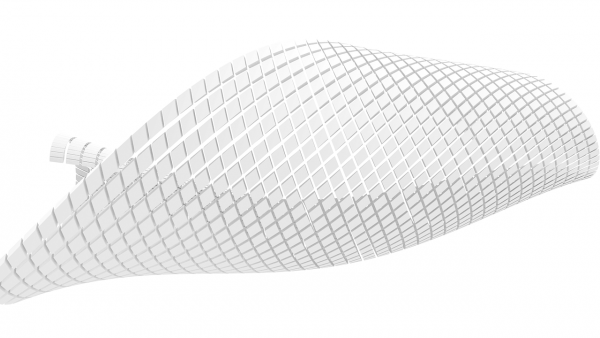

Als erster Automobilhersteller probierte Ford den Stratasys Infinite Build 3D-Drucker aus und machte damit einen großen und mutigen Schritt zur Integration des 3D-Drucks in die eigenen Fertigungsprozesse.

Dieser Drucker ist in der Lage, Komponenten und sogar Werkzeuge beliebiger Länge und Form zu erstellen. Es ist perfekt für die Herstellung eines Prototyp-Fahrzeugs, was eine teure und unnötig schwierige Aufgabe sein kann. Tatsächlich kann das Einrichten von Werkzeugen für einen Prototyp Monate dauern, während der 3D-Druck im schlimmsten Fall einige Stunden dauert. Das würde die Fahrzeugentwicklung deutlich beschleunigen.

Dank des 3D-Druckers konnte die Produktionsausfallzeit erheblich verkürzt werden. Die kaputten Werkzeuge an einer Montagelinie würden schnell und effizient ersetzt, wenn sie an Ort und Stelle gedruckt werden könnten, anstatt Stunden oder Tage zu warten.

Darüber hinaus eignet sich der Drucker gut für Komponenten von Kleinserienmodellen, darunter die Ford Performance-Fahrzeuge, wie der Ford Focus ST. Die Kosten für die Einrichtung von Werkzeugen zur Herstellung dieser Komponenten sind überhöht und machen den Druck finanziell viel attraktiver.

Ford sieht in den steigenden Anforderungen an die Kraftstoffeffizienz, sowohl seitens der Regierung als auch seitens der Verbraucher einen wichtigen Grund für den Einsatz des 3D-Drucks. Er behauptet, dass ein bedruckter Spoiler weniger als die Hälfte eines herkömmlichen Spoilers aus Gussmetall wiegen könnte.

Bugatti.

Der französische Autohersteller Bugatti ist für seine Exzesse bekannt und bringt diese Eigenschaft auch in seinen Umgang mit dem 3D-Druck mit ein.

Als erstes Unternehmen der Automobilindustrie hat Bugatti mit Hilfe des Laser Zentrums Nord in Hamburg einen massiven Titan-Bremssattel bedruckt. Das Bauteil befindet sich noch in der Erprobungsphase, so dass die volle Produktion noch nicht in vollem Gange ist.

Die Verwendung von bedrucktem Titan bietet einige Leistungsvorteile. Bugatti sagt, dass der Prozess so viel Gewicht wie möglich verliert, während gleichzeitig die Torsionssteifigkeit als Maximum erhalten bleibt. In einer Panik-Bremssituation kann der Bremssattel-Flex den Bremsweg verlängern, was den Unterschied zwischen Unfallvermeidung und Crash ausmacht.

Für den Bugatti Chiron wird zunächst ein Bremssattel aus Aluminiumlegierung verwendet, der durch ein traditionelles Schmiedeverfahren hergestellt wird. Die Serien-Frontsättel wiegen jeweils 4,9 Kg. Mit den 3D-Druckeinheiten sinkt das Gewicht auf nur noch 2,9 Kg.

Bei der Herstellung der Messschieber schmelzen vier Hochleistungslaser Titanstaub, der vom Drucker zugegeben wird. Auch hier gilt: Zeit ist eine Überlegung. Nach Bugatti dauert das Drucken von nur einem Messschieber allein 45 Stunden. Obwohl jede Materialschicht sofort abkühlt und somit die nächste verlegt werden kann, enthalten die Bremssättel 2.213 Schichten geschmolzenen Tintenstaub. Nachdem der gesamte Messschieber gedruckt wurde, muss er bei fast 1.300 Grad Fahrenheit in den Ofen gehen, dann wird er behandelt, um ein glattes und glänzendes Finish zu gewährleisten.

Mini.

Sogar bei der Herstellung des Minis spielt der 3D-Druck eine Rolle. Der britische Autohersteller im Besitz von BMW, hat vor kurzem angekündigt, ein neues Programm mit der Bezeichnung „Mini Yours Customized“ zu starten.

Im Grunde genommen wird ihre Akzeptanz in der Automobilindustrie mit zunehmender Zeit und Verbreitung von 3D-Druckern nur noch zunehmen.

Wenn Sie Unterstützung bei der Modellierung ihrer 3D-Druckerzeugnisse benötigen, sprechen Sie uns an. Wir helfen ihnen sehr gerne weiter.

Schon jetzt hat Mini den Ruf, ein Maß an Personalisierung für Autos im Massenmarkt anzubieten, das man sonst nirgendwo bekommen kann. Aber dieses neue Programm bringt die Dinge in Schwung. Mini-Besitzer können komplett angepasste Komponenten bestellen, wie z.B. eine Lichtabdeckung oder eine Türschwelle mit ihrem Namen, einem Lieblingssatz oder einem Design, das sich von anderen unetrscheidet.

Das Geheimnis dieser Fahrzeuganpassung der nächsten Stufe ist der 3D-Druck. Es ermöglicht Mini-Besitzern ein Einzelstück für ihr Auto anfertigen zu lassen und dass in jeder beliebigen Farbe und einem Design, das auf ihre Vorlieben zugeschnitten ist. Besitzer behalten die Fabrikkomponenten, wenn sie also jemals ihren Mini verkaufen oder tauschen wollen, können sie die kundenspezifischen Teile entfernen.

Großserienfertigung.

Trotz seiner Vorteile hat die 3D-Drucktechnologie noch nicht den Punkt erreicht, an dem sie für größere Produktionspläne effektiv ist. Das Hauptaugenmerk liegt auf der Zeit, da andere Methoden massive Mengen desselben Teils in schneller Reihenfolge erzeugen können.

Im Moment scheint es, dass der 3D-Druck eine Praxis ist, die für exotische Kleinserienfahrzeuge reserviert ist. Wenn die Technologie sich verbessert und die Druckgeschwindigkeit steigt, könnte es den Automobilherstellern möglich sein, schnelle Änderungen am Design eines Serienfahrzeugs vorzunehmen, wie z.B. die Korrektur eines unentdeckten Fehlers oder die Verbesserung eines Layouts auf der Grundlage von Kundenfeedback.

Eine weitere Anwendung in der Automobilindustrie ist in einem frühen Stadium: die Herstellung von Teilen für obskure Autos. Jay Leno hat gesagt, dass er einen 3D-Drucker benutzt, um Komponenten auf einigen seiner alten, einzigartigen Fahrzeuge auszutauschen. Diese Technologie hat das Potenzial, das unerfüllte Bedürfnis auf dem Markt für den durchschnittlichen Autobesitzer zu befriedigen.