Was der Unterschied zwischen CAD und CAE ist.

Dieser Artikel erläutert den Unterschied zwischen CAD und CAE. Aber lassen Sie uns zunächst klären, was man unter CAD genau versteht.

Vor nicht allzu langer Zeit, bevor CAD eingeführt wurde, machten die Ingenieure ihre Zeichnungen und Berechnungen von Hand. Heute wäre das viel zu aufwendig und nicht zu empfehlen. Die Ingenieure zeichneten nur drei verschiedene Ansichten auf ihr Blatt Papier und sie mussten ihr Projekt vereinfachen, um das Verhalten zu berechnen, wenn externe Kräfte angewendet wurden.

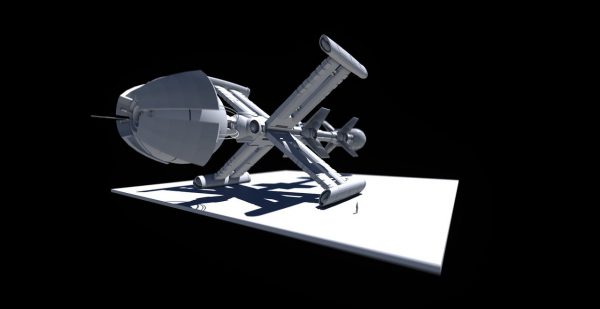

Mit der Einführung der computergestützten Konstruktionssoftware (CAD) war es den Ingenieuren plötzlich möglich, genaue 3D-Modelle zu erstellen. Mit weiteren technologischen Fortschritten können diese 3D-Modelle nun mit Hilfe von Computer Aided Engineering (CAE) Software analysiert werden.

Von manuellen zu automatisierten Berechnungen.

Auf dem Weg zum diplomierten Maschinenbauingenieur lernen die Studenten als erstes, wie man mechanische Probleme löst. In diesem Beispiel besteht unser mechanisches Problem darin, herauszufinden, wie sich der Wind auf dem Olympiaturm in München auswirkt.

Das erste, was wir tun, ist das Modell zu vereinfachen. Details und Merkmale des Turmes, die für eine grobe mechanische Berechnung nicht benötigt werden, werden eliminiert. Eigentlich sieht der Olympiaturm wie ein großer Mast aus, so dass in diesem Fall davon ausgegangen wird, dass der Turm ein Mast ohne Restaurant und Antenne ist.

Zu Beginn der Berechnungen machen wir eine grobe Zeichnung des Turms, die in unserem Fall eine einfache Linie auf dem Papier ist. Wir schätzen den Wind als eine konstante Kraft an der Spitze des Turms mit dem Ziel, das Momentum am Boden des Turms zu erhalten. Die Gleichung wäre einfach die Kraft des Windes mal die Höhe des Turmes.

Dieses Modell ist extrem vereinfacht. Jeder – einschließlich der Person, die für den Erfolg des Projekts verantwortlich ist – weiß, dass es in Wirklichkeit viel komplizierter ist und er möchte eine differenzierte Berechnung des Problems.

Gegenargumente für die einfache Annäherung, die wir gemacht haben, sind:

- Der Olympiaturm ist keine zweidimensionale Linie auf Papier, sondern eine komplexe dreidimensionale Geometrie.

- Der Wind ist keine einzelne, konstante Kraft, sondern eine dynamische Kraft, die Turbulenzen und andere Effekte verursacht.

Um dies zu berechnen, nutzen wir die Leistungsfähigkeit von CAE.

Der Unterschied zwischen CAD und CAE.

CAD ist die Abkürzung für Computer Aided Design, was bedeutet, dass eine Produktidee am Computer visualisiert wird. CAE ist die Abkürzung für Computer Aided Engineering, also die Analyse der entworfenen Visualisierung. Kurz gesagt, der Unterschied zwischen CAD und CAE kann so ausgedrückt werden: CAD konstruiert ein Produkt und CAE simuliert es.

Die Vorteile des Einsatzes von Computern im Design gegenüber den Methoden der alten Schule liegen auf der Hand. Die Hauptvorteile der 3D-CAD-Software gegenüber der 2D-Zeichnung sind unter anderem die folgenden:

- Eine 3D-Version des Objekts kann erstellt werden. Ingenieure und Produktionsmitarbeiter können die Form und die Eigenschaften der entworfenen Geometrie besser verstehen. Darüber hinaus können einige Geomtrien extrem kompliziert und schwierig sein, wenn nicht sogar unmöglich zu verstehen, ohne sie in drei Dimensionen zu sehen.

- Änderungen an der Geometrie können sehr einfach vorgenommen werden, da die Software das Produkt nach jeder Änderung neu berechnet. Außerdem erkennt und warnt Sie das CAD-Programm bei Fehlern in ihrer Geometrie, die z.B. zu einer Kollision von beweglichen Teilen führen würden.

- Der wohl wichtigste Vorteil ist, dass ein CAD-Modell in ein Mesh transformiert und zu Analyse- und Testzwecken simuliert werden kann.

CAE Tools haben auch viele Vorteile wie zum Beispiel:

- Es werden nicht so viele Prototypen benötigt und die Gesamtentwicklungskosten des Projekts gesenkt.

- CAE reduziert das Fehlerpotenzial in der Konstruktion.

- Die Anwender vermeiden Over-Engineering, da sie sofort erkennen können, ob sich die Änderungen am Produktdesign auf die Performance auswirken, so dass sie frühzeitig entscheiden können, ob es sich lohnt, die Entwicklung fortzusetzen oder ob sie die Designversion nach den ersten Simulationen fallen lassen sollten.

- Die Auswirkung der Änderung einiger Parameter auf das Produkt kann untersucht werden.

All dies führt dazu, dass CAE dazu beiträgt, die Kosten und die Markteinführungszeit für ein Produkt zu reduzieren.

Der Unterschied zwischen CAD und CAE: der Meshing Prozess.

Kommen wir also zurück zum Kernpunkt: Was ist der Unterschied zwischen CAD und CAE? Auf den ersten Blick sehen die Modelle von CAD- und CAE-Software fast gleich aus. Bei genauerer Betrachtung zeigt sich jedoch, dass sie sich grundlegend unterscheiden. Beide haben die Form des Produktes, haben aber mathematisch gesehen nicht viel gemeinsam.

Es gibt verschiedene Möglichkeiten, geometrische Elemente zu einer 3D-Geometrie zu kombinieren. Höchstwahrscheinlich werden CAD-Modelle als eine Zusammenstellung von Volumen oder Körpern mit Parametern wie der Dichte des eigentlichen Materials entworfen. Das für die CAD-Modellierung weit verbreitete Modell ist ein parametrisches Modell mit einer Konstruktionshistorie. Dies hat den Vorteil, dass die Features nachträglich geändert werden können, so dass 3D-Objekte als Kombination von geometrischen Formen mit Parametern erstellt werden können.

In einer CAE-Umgebung wird das CAD-Modell während des Post Processing in ein Mesh umgewandelt. Das Mesh besteht entweder aus Würfeln, Quader oder Tetraeder, also in der Regel aus Polygonnetzen. Daher ist es legitim, ein CAD-Modell mit einer Vektorgrafik zu vergleichen, während ein CAE-Modell als pixeliges Modell bezeichnet werden kann.

Berechnung und Post-Processing.

Dies zeigt deutlich, dass man ein CAD-Modell nicht einfach in ein CAE-Modell umwandeln kann. Die Modellierung von Spheres zum Beispiel wird ein Problem für Sie sein. Dies ist bei Volumen mit Ecken nicht möglich, aber wenn die einzelnen Volumen des Meshes klein genug sind, kann es eine gute Annäherung sein.

Nach Abschluss des Post-Processing beginnt die Berechnung. Dies unterscheidet sich je nach dem zu lösenden Problem und der Art der Simulation, wie z.B. Finite-Elemente-Analyse, numerische Strömungsmechanik oder thermische Analyse.

Der Ingenieur wird das CAD-Modell vereinfachen wollen, weil es wegen der fehlenden Rechenleistung nicht möglich sein wird, ein perfektes Ergebnis zu erreichen. Im Gegensatz dazu möchte ein Ingenieur, der ein CAD-Modell verwendet, eine perfekte Darstellung des Modells erstellen, das er im Sinn hat. Die Annäherungen, die gemacht werden, sind sehr genau. Denken Sie nur daran, dass auch die Betonsäule des Olympiaturms nicht perfekt rund ist, sondern kleine Kanten hat, an denen die Beplankung des Betons angebracht wurde. Sobald dies abgeschlossen ist, sind die nächsten Schritte das Erstellen des Meshes und das Einrichten der Simulation.

Wie Sie den Umgang mit Simulationssoftware erlernen.

Nachdem wir nun den Unterschied zwischen CAD und CAE sowie deren Vorteile diskutiert haben, stellt sich zwingend die Frage: Wie kann ein CAD-Anwender mit der Engineering-Simulation beginnen?

Diese Frage werden wir in kommenden Beiträgen etwas näher diskutieren.