Wie Sie mit MakeVR schneller den Umgang mit 3D-Modellierungssoftware erlernen.

Dank der flächendeckenden Einführung des 3D-Drucks sind heute die Türen zur Kreativität weit geöffnet. Heutzutage kann jeder, der noch 200 € übrig hat, ein Gerät erwerben, mit dem er fast jedes beliebige Objekt herstellen kann.

Aber es gibt immer noch eine große Barriere zwischen einer Idee im Kopf und der Umsetzung dieser Idee in ein greifbares Objekt – die 3D-Modellierungssoftware.

Das Problem ist, dass praktisch jede 3D-CAD-Software eine ziemlich steile Lernkurve hat. Ob Sie ein kostenloses Tool wie Blender oder ein teures professionelles Programm wie AutoCAD oder Solidworks verwenden, es erfordert einiges an technischem Geschick, um alles über die einfachsten Formen hinaus zu erstellen.

Es ist besonders schwierig, wenn Sie noch keine Erfahrung mit CAD- oder 3D-Modellen haben. Da es keine Grundlage gibt, auf der man aufbauen kann, muss man sich oft stundenlang Tutorial-Videos ansehen, um herauszufinden, wie man eine scheinbar einfache Aufgabe bewerkstelligen kann (z.B. ein zylindrisches Loch in etwas zu schneiden).

Das in Kalifornien ansässige Startup Sixense hat sich zum Ziel gesetzt, diese Barriere zu durchbrechen.

„Wir wollten die 3D-Modellierung demokratisieren“, sagte Steve Hansted, Director of Business Development, gegenüber Digital Trends. „Unser Ziel war es, jedem, unabhängig von Alter und Erfahrung, die Möglichkeit zu geben, in eine professionelle CAD-Engine zu kommen und Geometrie zu bauen – mit einer sehr flachen Lernkurve.“

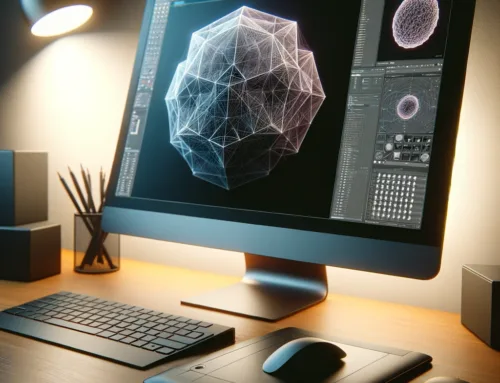

Das Ergebnis dieser Arbeit ist ein Programm mit der Bezeichnung MakeVR – eine 3D-Modellierungsplattform, die im Gegensatz zu den meisten CAD-Programmen nicht in einer herkömmlichen Desktop-Umgebung ausgeführt wird. Stattdessen greifen Anwender über die Virtual-Reality-Plattform HTC Vive auf die Software zu und nutzen Sie.

Da mehr Leute PC`s besitzen als eigene Virtual Reality Setups im Raummaßstab, ist es möglich, dass man mit VR-only MakeVR aus geschäftlicher Sicht ein wenig benachteiligt sein könnte, aber aus kreativer Sicht bietet das Arbeiten in Virtual Reality MakeVR eine Reihe von deutlichen Vorteilen.

„Der Unterschied zu herkömmlichen Modellierungsprogrammen ist, dass MakeVR sprunghafter und taktiler ist“, sagt Patrick Daniels, ein freiberuflicher Designer und Modellierer, der die DT-Zentrale besuchte, um die Software zu testen. „Damit bekommt man räumliches Vorstellungsvermögen, während ich, wenn ich mich mit Maus und Tastatur hinsetze, meist nur auf ein Modell starre. Aber ich könnte mir vorstellen, mit dieser Software an ganzen Umgebungen zu arbeiten“, erklärte er.

Das ist die Magie des Ganzen. Anstatt in einer begrenzten, zweidimensionalen Umgebung auf ihrem Monitor zu modellieren, ermöglicht MakeVR dem Benutzer, sich vollständig in einen virtuellen kreativen Raum einzutauchen und Objekte mit zwei Händen zu manipulieren – ganz so, wie wenn Sie mit festen Materialien in der realen Welt arbeiten würden. Wie Daniels es so eloquent ausdrückte: „Es passt einfach gut in dein Gehirn.“

Am spannendsten ist jedoch, dass dies der Anfang ist. MakeVR wurde vor ein paar Wochen auf Viveport gestartet, aber Hansted sagt, dass das Projekt alles andere als vorbei ist.

„MakeVR wird sich ständig weiterentwickeln“, erklärte er. „Im Moment bezeichnen wir es als ein fortgeschrittenes Freiformmodellieren.“ Sie haben Zugriff auf die Booleschen Werkzeuge der CAD-Engine und einige andere Dinge. Aber es gibt noch viel mehr, was wir im ersten Release nicht freigeschaltet haben. Von hier aus fügen wir Werkzeuge für Dinge wie Präzisionsausrichtung, Teamwork, Physik hinzu – und schließlich werden so viele der Werkzeuge aus MakeVRs zugrundeliegender CAD-Engine freigeschaltet, wie in einer VR-Umgebung sinnvoll und von den Anwendern gewünscht wird.“

Sobald Sie die Software bei der Arbeit gesehen haben, ist es schwer, ihre Phantasie am Laufen zu halten. Der 3D-Druck ist der Bereich, in dem MakeVR derzeit am meisten zu Hause ist, aber in nicht allzu ferner Zukunft könnte die Technologie leicht auf andere Bereiche ausgedehnt werden – zum Beispiel auf das Gamedesign.

Stellen Sie sich fünf Entwickler aus der ganzen Welt vor, die alle an verschiedenen Aspekten eines Projekts im selben virtuellen Raum arbeiten. Man kann an Gebäuden arbeiten, während ein anderer an der Charaktergestaltung arbeitet und noch ein anderer am Himmel und der Umgebung. Dies alles könnte virtuell und kollaborativ in einem 3D-Raum geschehen, in den jeder Benutzer eingetaucht ist. So etwas könnte einen großen Einfluss auf die Spieleentwicklung haben.

Vielen Dank fürs Lesen.