Everything you wanted to know about CPQ.

Again and again you hear or read about these 3 letters. But what does CPQ actually mean? And what is the enormous advantage for companies behind this abbreviation?

The abbreviation stands for Configure Price Quote (CPQ).

This item describes a process chain in sales and distribution or in sales processes. In order to make it as easy as possible to sell products (or services) that are rich in variants and customer-specific, CPQ software is required that fulfils the following functions:

- Product 3D configurator (Configure)

- Pricing (Price)

- Quotation preparation (quota)

QPC Software supports the user (in most cases sales staff) within a quotation process. This speeds up the bidding process enormously. The core functionality of a CPQ system is essentially the product configuration. A CPQ process stands and falls with it.

The most important – the product configuration.

The product configuration should be rule-based. The advantages are obvious:

- Creation of error-free and complex quotations without product experts

- Accelerated order and order processes

- Automated order processing

- Guided Selling for sales, dealers and customers

- Reduction of the training period for new sales employees

- Minimization of the loss of know-how due to the loss of a long-standing sales employee cost containment

- Centralized product knowledge through transfer of product knowledge into software

- Optimized and accelerated sales processes through increased standardization and automation

- Reduction of product complexity

CPQ in the Age of Industry 4.0

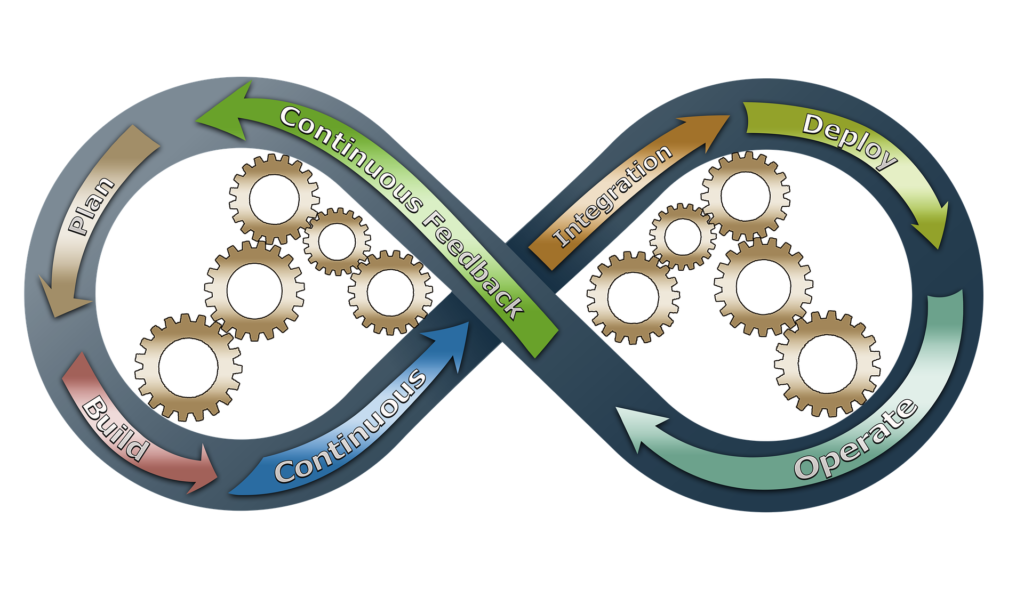

Over the years, however, many CPQ systems have not only limited themselves to pure product configuration, price calculation and quotation preparation – they have been further developed in many directions, e.g. speedmaxx from ACATEC. This CPQ system extends the process chain described above right through to production. This is done, for example, by connecting the customer`s entire data processing landscape (ERP, PDM, CAD etc.).

The classic product configurator closes the gap between sales and production. Thus, an order including production data can be created from an offer without loss of resources. Especially with regard to Industry 4.0, a clear gain in quality and time.

Thus, the complete process chain from sales/end customer to production can be covered.